I went to FISMA held at Tokyo Big Sight on September 18th and 19th.

There were many companies exhibiting, and there were many interesting things.

I would like to introduce some of them.

First up is the ultrasonic fusing cutter from Suzuki Machine Re-Engineering Co., Ltd.

It can be used on almost any material that melts, such as polyester or nylon.

The feature of this ultrasonic welding cutter is that when cutting textile, etc., it not only cuts, but also melts and cuts with ultrasonic waves and prevents fraying at the same time.

When I was shown the actual cut fabric, there was no fraying and it was cut smoothly.

It may save you the trouble of using a lock sewing machine and make your sewing work easier.

The next product I'd like to introduce is a sublimation printer from Systemography Co., Ltd.

Print it on paper and then transfer it to textile.

Although it takes a little time and is not suitable for mass production, it is possible to print with the texture of the fabric better than regular printing.

When I looked at the printed textile, it blended in as if it had originally been the pattern, and the fabric still had its luster.

I thought that this method should be used to print high-end clothes produced in small batches.

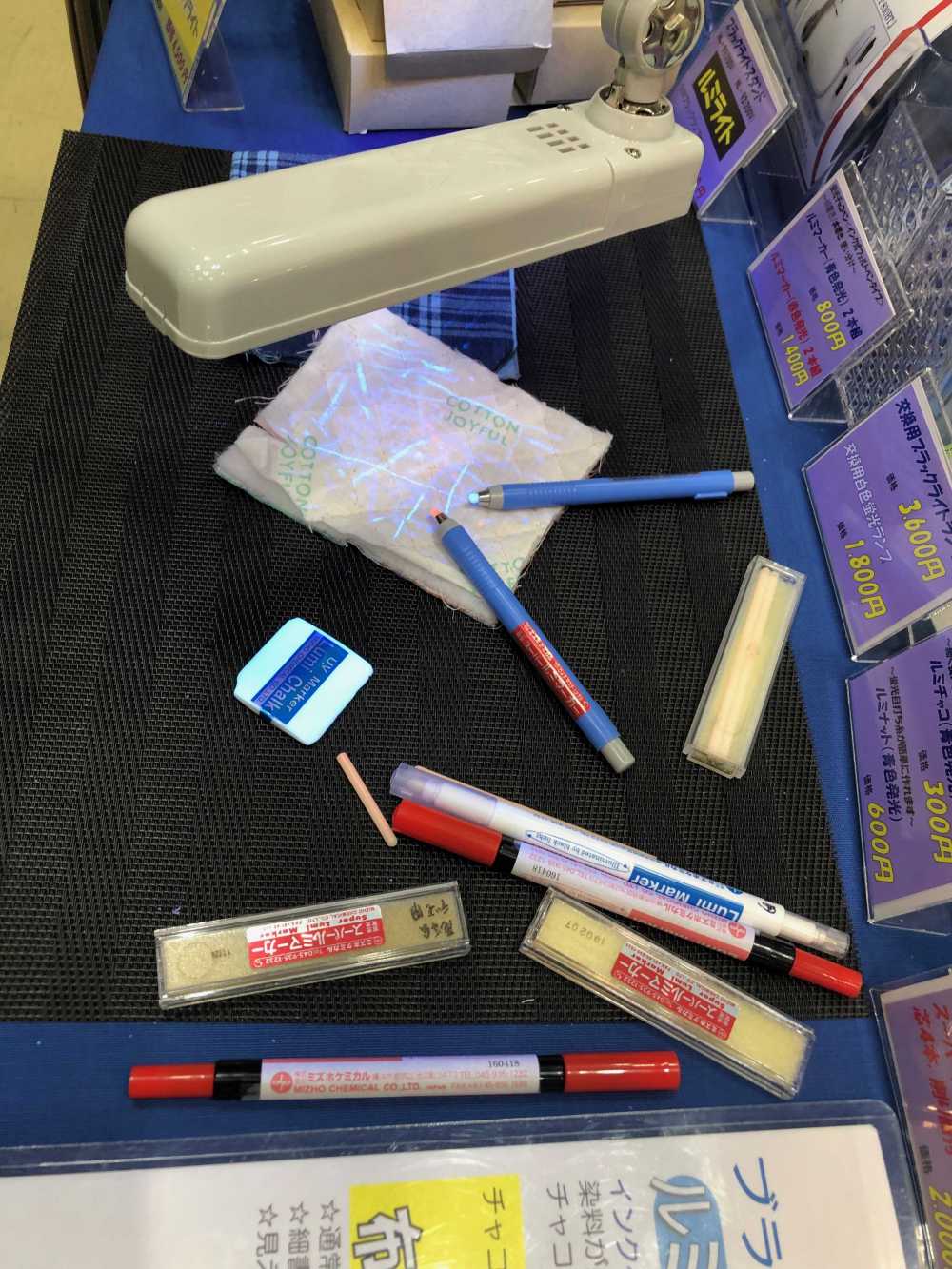

The last thing I would like to introduce is Mizuho Chemical Co., Ltd.'s chaco or marker that becomes visible when exposed to blue light.

Without blue light, the markings are not visible at all, and when blue light is applied, the markings become clearly visible.

Convenient for marking visible areas such as button attachment positions and pocket attachment positions.

The area where you drew the chaco will glow fluorescently, so sewing will be fun.

It was my first time to go to an exhibition like this, so it was fun to see all the big machines for companies that I had never seen before.

There are other useful products designed to make making clothes easier, and I learned a lot from them.